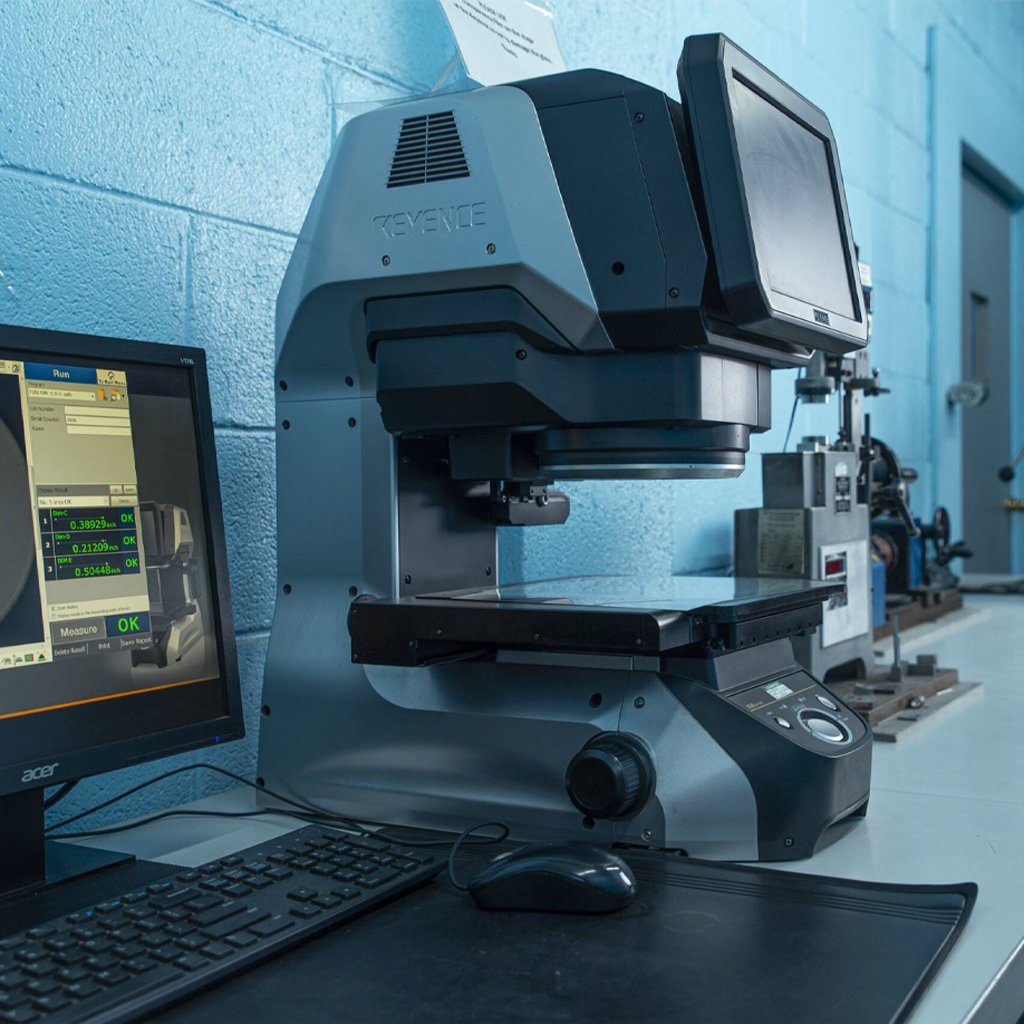

Quality Control

The quality staff at Elyria Spring & Stamping is well versed in Level 3 PPAP requirements as dictated by AIAG standards. Our documentation matches all that is required for these types of PPAP submissions. Many of our components are sold through 2nd and 3rd tier automotive suppliers who in turn supply to Ford, GM, Chrysler, Nissan, Mitsubishi, and Honda. These PPAP’s have been successfully submitted with full approval from our customers.

Beyond any PPAP requirements, Elyria Spring & Stamping caters to our customers by submitting new product submissions meeting individual requirements. Our staff in quality extends their expertise in aiding our customers in many different types of 1st article submissions. In addition to these items, it is also a standard practice to involve cross functional teams when new parts are ordered by our customers. These advance planning activities involve personnel from purchasing, tool room, production and quality.

Quality Control Process

- Review the customer’s design by all departments to assure that we can produce the product and have the resources necessary to measure and document what the customer’s blueprint is designating.

- Produce a quality product in the most efficient method.

- Conduct a review after production by the same personnel who conducted the initial review to evaluate the thoroughness of the advance plan.

- Record any lapses so they can be used in future advance planning activities.

ISO Certified

As an ISO certified company, we continually look at opportunities to enhance both our products and our quality systems. To this end, we conduct ongoing SPC training with all of our production personnel. The goal of this training is to have quality and production work together to obtain common goals. Our Registrar will continue to perform annual surveillance audits. Traditionally, these surveillance audits have come out either with zero non conformances or very minor non conformances. Our registrar reports that this is due to the excellent internal auditing that occurs within the company on an annual basis.