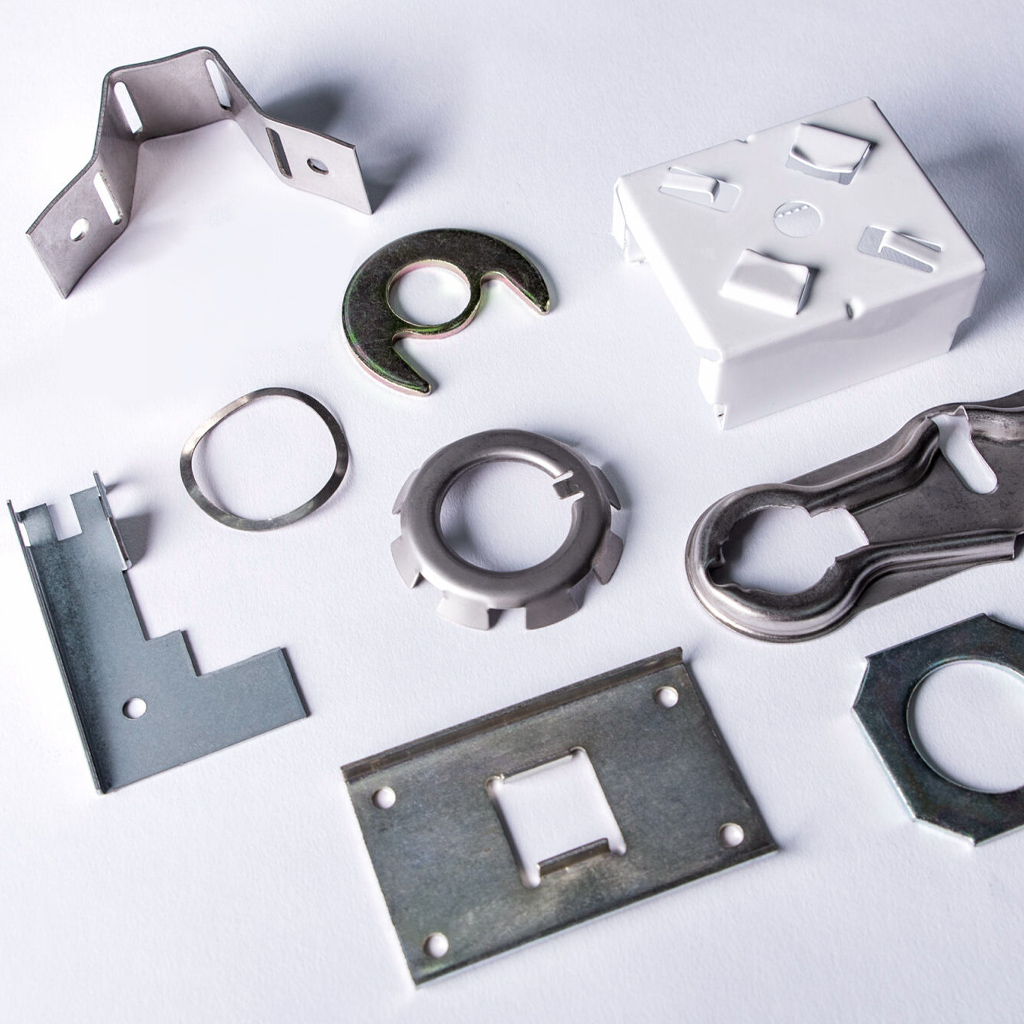

Metal Stampings & Precision Products

Exceeding the expectations

of leading manufacturers

CUSTOMER VOICES

Frequently Asked Questions

Metal stampings are essential components used across automotive, aerospace, medical, electronics and industrial applications. These precision-engineered parts comprise components found in myriad places from vehicle body panels to intricate medical devices. Two critical characteristics should include durability and the component’s adherence to exact tolerances, to supply reliable performance in products that demand precision and strength.

Metal stamping is a manufacturing process that transforms flat metal sheets into specific shapes using specialized dies and precision tools. This high-precision technique, mastered by the staff at Elyria Spring & Stamping, creates complex components through processes like punching, bending and forming. The result is durable, accurately designed parts that maintain tight tolerances for various industrial applications.

The four primary metal stamping types are progressive die stamping, transfer stamping, deep draw stamping, and fourslide stamping. Each method offers unique advantages for creating components that meet performance requirements across a wide variety of industries. Exact specifications can help determine which method or type of metal stamping will best suit the purposes of the application and tolerances and performance desired. Elyria Spring & Stamping specializes in these techniques, delivering custom-engineered solutions that maintain exceptional accuracy while meeting specific design requirements across industries.

A punch press is a specialized machine tool designed to work sheet metal through controlled force. The machine’s key components, including the frame, ram, bed, and brake, work in concert to cut, form, pierce, and shape metal with exacting precision. The tonnage rating indicates the force the machine can apply. The range available through the punch press machines we operate, allows us to handle everything from delicate small-scale parts to robust components requiring significant forming pressure.